PEB Shed Manufacturer in Ahmedabad: Smart Infrastructure for Smart City Businesses

Introduction

PEB Shed Manufacturer in Ahmedabad is redefining how businesses build across Gujarat and beyond. In an era when smart cities demand resilient yet flexible infrastructure, pre-engineered steel sheds are rapidly becoming the preferred choice.

Here’s what you’ll learn:

- Why Ahmedabad is a hub for PEB (pre-engineered building) manufacturing

- Key features and benefits of using PEB sheds

- How to choose the right PEB shed manufacturer

- What smart city businesses stand to gain

What Is a PEB Shed? / Quick Context (H2)

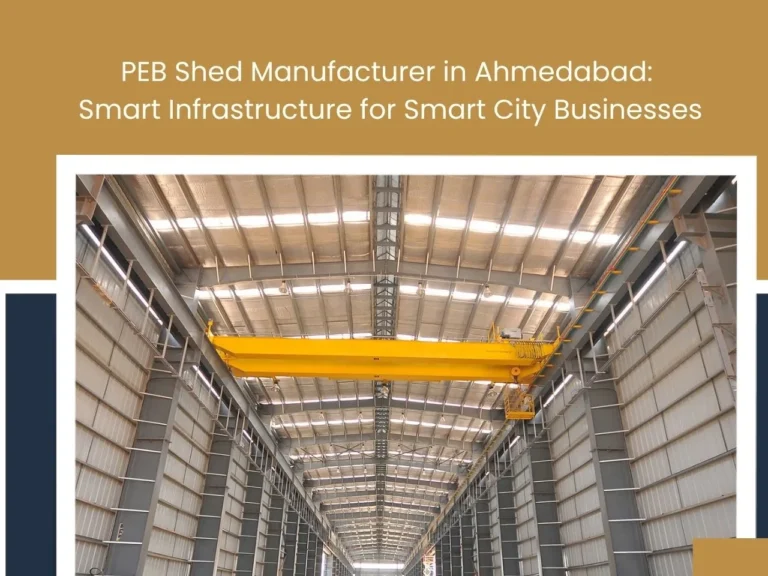

A PEB shed (Pre-Engineered Building shed) is a steel building system fabricated with prefabricated structural members, assembled on site with bolted connections. It’s engineered in the factory, not at the site.

Why Ahmedabad Is a Key Hub for PEB Sheds (H2)

Ahmedabad has emerged as a center for PEB manufacturing thanks to these advantages:

- Ahmedabad is centrally located to major industrial corridors in Gujarat, reducing logistics cost.

- Its skilled fabrication labor and steel supply chain are well developed.

- Several local firms such as Nagmani Fabtech have already delivered over 10 lakh sq ft of PEB work in the region, enhancing their local reputation and capabilities.

- Firms like Fabweld Structure emphasize durability, fast installation, and attractive aesthetic value.

- Companies such as Prem Infra serve industrial clients across Gujarat with customizable PEB sheds.

Thus, Ahmedabad combines cost, quality, and proximity advantages for businesses looking for smart infrastructure.

Key Features & Technical Details (H2)

Structural & Material Specs

- High-tensile steel frames with hot-dip galvanization or protective coatings

- Roof and wall panels: sandwich insulation, trapezoidal profiles, or standing seam systems

- Clear spans up to 60–100 m depending on design

- Modular bay widths of 6–12 m or larger, with flexibility to expand

- Pre-designed for loadings: wind, seismic, snow (if applicable)

Speed & Cost Efficiency

- Factory prefabrication reduces on-site work by 40–60%

- Assembly is mostly bolted (minimal on-site welding)

- Reduced construction schedule — buildings that might take months via conventional methods can be done in weeks

Durability & Maintenance

- Corrosion resistance via coatings or zinc layers

- Low maintenance, especially on roofing and cladding

- Ability to expand or dismantle for relocation

Customization & Integration

- Doors, windows, skylights, mezzanine floors, crane beams

- Insulation, ventilation, HVAC, lighting systems

- Integration with solar panels or smart sensors

Typical Costs & Timeline

- Rough ballpark in Gujarat: ₹1,300–2,500 per sq ft (depending on finish, insulation, design complexity)

- Lead time: design (2–4 weeks), fabrication (4–8 weeks), erection (2–4 weeks) — total ~8–16 weeks

Why It Matters for Smart City Businesses (H2)

Smart city businesses—warehouses, logistics hubs, cold storage, urban factories—demand infrastructure that is modular, fast, energy-efficient, and scalable. PEB sheds deliver exactly that.

- Scalability & modularity: Businesses can expand capacity without full rebuilds.

- Reduced downtime: Faster build time keeps operations on schedule.

- Efficiency & sustainability: Integrated insulation, daylight provisions, and energy systems enable green operations.

- Cost control: Lower lifecycle cost compared to traditional brick-and-mortar structures.

In essence, a PEB Shed Manufacturer in Ahmedabad provides the backbone for smart infrastructure in developing urban corridors.

Choosing the Right Manufacturer: What to Compare (H2)

Here’s a comparison of what to check:

| Factor | What to Look For | Why It Matters |

|---|---|---|

| Experience & portfolio | Completed industrial, warehouse, or smart city projects | Indicates capability to deliver complex jobs |

| Engineering capacity | In-house design, steel detailing, 3D modeling | Avoids outsourcing delays and miscommunication |

| Quality & certifications | ISO, material certificates, third-party tests | Ensures structural safety and reliability |

| Local presence & supply chain | Factory or workshop close to Ahmedabad | Cuts transport and lead times |

| After-sales & support | Warranty, repair service, spare supply | Keeps the building reliable over many years |

Some Ahmedabad manufacturers to consider:

- Nagmani Fabtech (strong track record)

- Fabweld Structure (durability and aesthetics)

- Jenish Infra (turnkey PEB projects)

- Khodiyar Engineers (innovative local manufacturer)

- Ram Engineers (solid regional presence)

Best Practices & Tips (H2)

- Begin early with geotechnical and load studies — base preparation influences steel footings.

- Use 3D design & BIM modeling to avoid clashes and delays.

- Plan for expansion from the start — leave buffer zones.

- Validate material certificates on arrival — thickness, grade, coating values.

- Ensure skilled erection crew with project supervision.

- Schedule periodic inspections after 5–10 years for bolting, corrosion checks.

FAQs

Q1: What is a PEB Shed Manufacturer in Ahmedabad?

A: It’s a company based in Ahmedabad that designs, fabricates, and erects pre-engineered steel sheds for industrial, warehouse, and commercial use.

Q2: How much does a PEB shed cost per square foot in Gujarat?

A: Typical ballpark is ₹1,300–2,500 per sq ft, depending on complexity, insulation, and finishes.

Q3: Can PEB sheds withstand Gujarat’s climate (heat, monsoon)?

A: Yes. Proper coatings, drainage, and design for wind and rainfall ensure durability even in harsh climate.

Q4: Is expanding or relocating a PEB shed feasible?

A: Absolutely. Many PEB sheds are designed for modular expansion or partial dismantling and relocation.

Key Takeaways

- PEB Shed Manufacturer in Ahmedabad is enabling smart infrastructure in Gujarat’s industrial zones.

- PEB sheds offer fast, durable, modular, and cost-efficient infrastructure.

- Choose manufacturers with local presence, engineering capability, and proven portfolios.

- Smart city businesses can gain flexibility, energy efficiency, and lower lifecycle cost through PEB systems.

Conclusion

If you’re planning industrial, logistics, or commercial infrastructure in Gujarat, partnering with a PEB Shed Manufacturer in Ahmedabad is a smart move. The blend of speed, cost control, and future-proof design aligns perfectly with smart city goals. What’s your take? Share below.